here’s no doubt that silicon (Si) ranks as the dominant chip technology in the industry. In contrast with Si, SiC is characterized by high thermal conductivity. As a result, MOSFETs made from SiC could withstand junction temperatures up to 600˚C, which meets the requirements of industrial drives. In addition, SiC does well with a much higher current and voltage due to its high breakdown voltage and low on-state resistance.

With all that in mind, recently a handful of companies are collaborating to exploit SiC in an attempt to improve the efficiency of electric vehicles. For instance, the collaboration between STMicroelectronics (ST) and Semikron (discussed below) has yielded a new SiC power semiconductor product that is aimed at designs in electric vehicle traction drives.

In this article, we’ll examine the highlights of recent breakthroughs made by companies through the exploitation of SiC for power semiconductor components.

ST’s SiC MOSFETs Meet Semikron’s DPD Technology

The recent announcement by the two companies is about ST supplying its SiC technology to Semikron. But this is the result of a four-year technical collaboration by the two firms to help advance innovation in the automotive industry. ST’s advanced third-generation SiC technology, STPOWER SiC MOSFETs, together with Semikron’s fully sintered, low stray inductance direct pressed die (DPD) technology, has led to the fabrication of robust power modules, called eMPack power modules. The modules are well suited for use in electric vehicle traction drives.

While STPOWER SiC MOSFETs control per switching in the main EV traction inverter, Semikron’s fully sintered DPD assembly process enhances module performance and reliability, according to the companies.

Close-up view of Semikron’s eMPack EV power module. Image used courtesy of STMicroelectronics

The collaboration yielded 750 V and 1,200 V eMPack power module platforms. The modules find applications in electric drive system inverter architectures covering a power range from 100 kW to 750 kW and battery systems ranging from 400 V to 800 V.

Regarding the collaboration with Semikron, the Executive Vice President at ST, Edoardo Merli, remarked that Semikron’s advanced scalable eMPack family of power modules is ready to make a significant contribution towards zero-emission motoring.

SiC Power Modules for Next-gen EVs

Another recent development in the automotive industry has seen the EV manufacturer, NIO, adopt SiC power modules from onsemi for applications in the development of state-of-the-art EVs. The adopted SiC component from onsemi is a series of VE-Trac Direct SiC power modules.

The VE-Trac Direct SiC product is an integrated single-side direct cooling (SSDC) power module in a six-pack configuration with a low turn-on resistance of 1.7 mΩ. These power modules provide longer range, higher efficiency, and faster acceleration for electric vehicles, says onsemi. According to the manufacturers, the VE-Trac product family is designed to effortlessly scale EV power outputs, accelerating the adoption of hybrid and battery EVs (BEV).

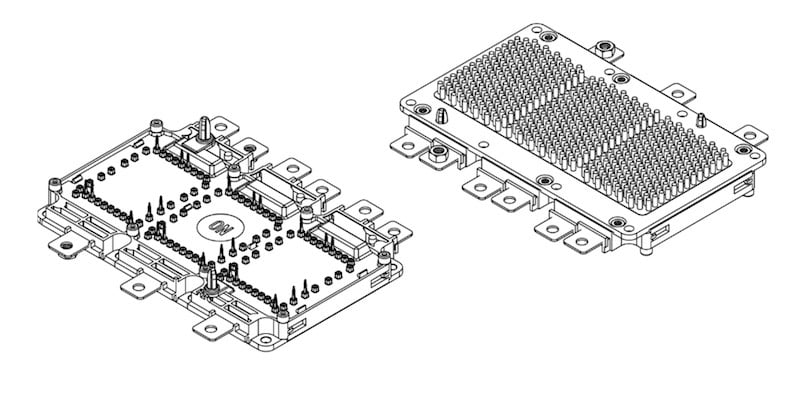

VE-Trac Direct power module. Bottom view (left), top view (right). Image used courtesy of onsemi

The EVs manufactured with the VE-Trac Direct SiC power modules have a robust traction inverter that converts battery energy into large amounts of torque and acceleration. The second-generation SiC MOSFET technology from onsemi gives the traction inverter an advanced level of performance and efficiency, says the company.

One of the products in this generation, NVXR17S90M2SPB, boasts a maximum junction temperature of 175˚C. This makes it suitable for continuous operation and could be adopted in traction inverter power applications ranging from 100 kW to 250 kW. The VE-Trac product family features an integrated pin fin baseplate that enables direct liquid cooling and easy assembly which allows maximum power output and more efficient thermal dissipation.

Commenting on the collaboration, senior vice president at NIO, Alan S. Zeng, noted that the VE-Trac Direct SiC traction power modules offered the best efficiency during testing, allowing NIO to extend the New European Driving Cycle (NEDC) project range by 4% compared to the current silicon solution.

SiC MOSFETs Employed in EV Charging Systems

For its part, Wolfspeed back in April unveiled what it claimed as the world’s largest 200 mm SiC fab with the goal of meeting the growing demand for SiC semiconductor devices in the automotive industry. More recently, Wolfspeed announced it’s collaborating with Rhombus Energy Solutions to employ its SiC technology in Rhombus’ EV charging infrastructure products.

Silicon carbide enables more developments in systems that provide bi-directional EV charging such as these EV charging systems from Rhombus. Image used courtesy of Rhombus

The collaboration involves Wolfspeed providing SIC MOSFETs for applications in Rombus’ EV2flex line of charging infrastructure.

According to Deanne Davidson, Senior VP and GM of Rhombus Energy Solutions, Wolfspeed’s Silicon Carbide MOSFETs are critical components to meet the demands in the growing DC fast-charging market for EVs.

The EV2flex infrastructure manufactured by Rhombus includes a family of products that enable fast, bi-directional charging and efficient energy storage. SiC MOSFETs are said to provide greater efficiency, higher power density, and faster charging times.